Hi all,

my name is Craig Barbour, I am a 4th (and final woo!) year BTechEd student at Glasgow University. I am also building a reprap machine as part of my final year project. Unlike the Braes project I have sourced the majority of the parts myself and my parts are FDM prototyped instead of laser cut parts. I think Brian said on this blog that sourcing components may be more enjoyable and satisfying, it was but so troublesome I would advise against. (Royal mail owe me circuit boards).

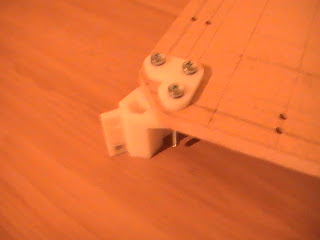

I will post some pictures of my progress so far so you can see how it looks and the similarities and differences between the Braes kit and mine.

Look forward to seeing the Braes progress as well and sharing news, problems and ideas

Feel free to get in touch for any info.

Craig